Geosynthetics are artificial substances utilized to enhance soil conditions. The term originates from the combination of "Geo," referring to earth or soil, and "Synthetics," denoting man-made materials. Geosynthetic materials are applied either on or within the soil. Geosynthetics are commonly produced from petrochemical-based polymers, commonly known as "plastics," which are biologically inert and resistant to decomposition caused by bacteria or fungi.

Geosynthetics have become essential in civil engineering, widely used in road construction and other fields. Their inclusion has revolutionized road design and stability. Not using geosynthetics in road construction can result in reduced stability, increased maintenance, poor drainage, soil erosion, higher construction expenses, and a limited road lifespan. The absence of these materials compromises the road's durability, safety, and performance, leading to more frequent repairs and potential failures.

A key player in this domain is Megaplast, India's leading geomembrane manufacturer. Their top-notch HDPE and LLDPE geomembranes and agriculture films have significantly contributed to infrastructure and agricultural needs.

Let’s talk about how Geosynthetics first came into use in Road Construction.Â

The history of Geosynthetics

Geotextiles were first used in US road construction during the 1920s. Later, during the 1960s, woven geotextiles were adopted for erosion control, and in the 1970s, both woven and nonwoven geotextiles were used in various applications, like retaining walls and underdrains.

Over the past four decades, geosynthetics have been extensively used in forest road applications, drainage construction, simple walls, and subgrade stabilization. They were employed in reinforced fills for erosion control and as interlayers within pavements. Additionally, geosynthetics have been crucial in early soil reinforcement for MSE (Mechanically Stabilized Earth) retaining walls, separation, and drainage projects.

Types of Geosynthetics for Road Construction

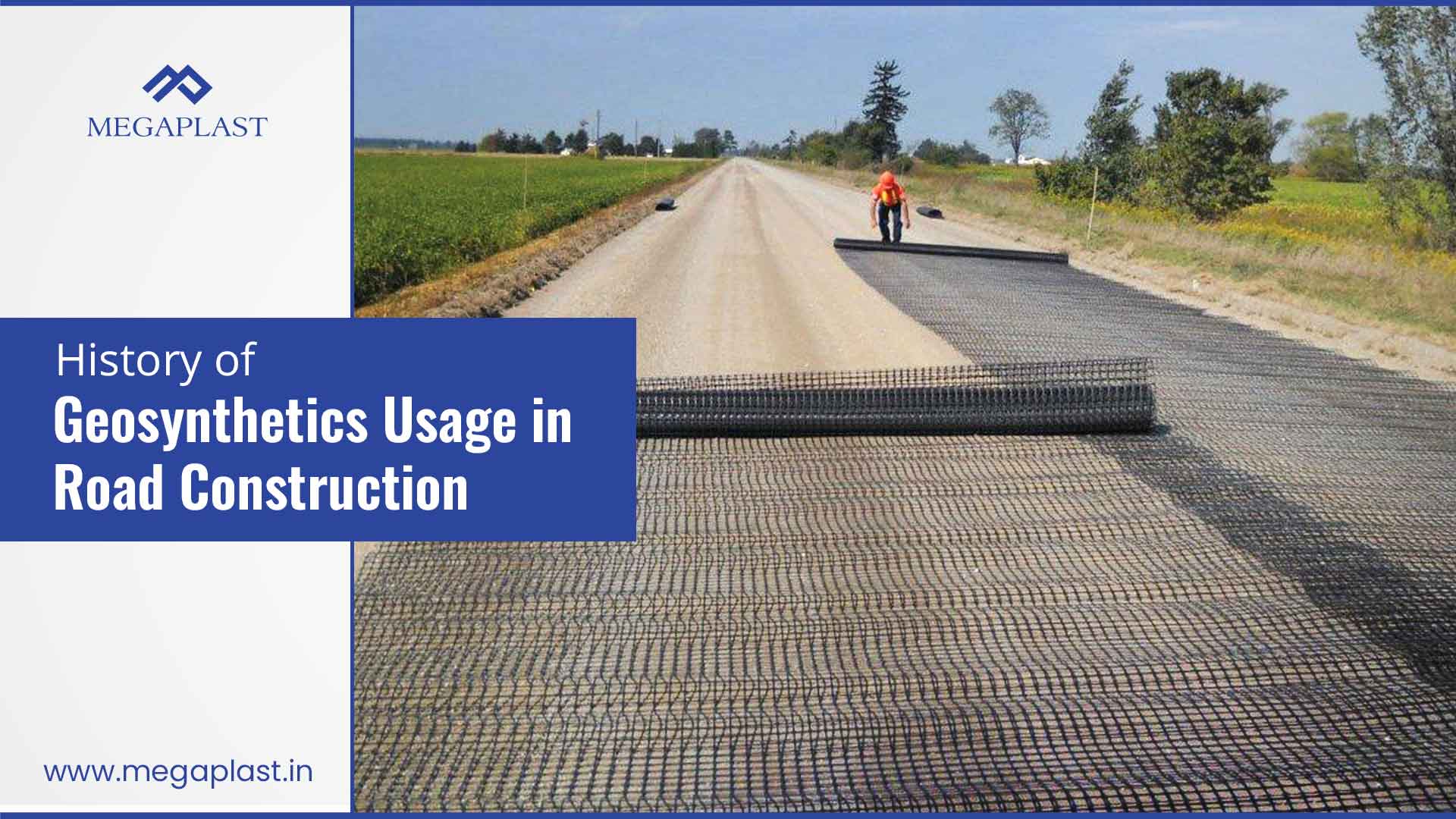

Several types of geosynthetics are commonly used in road construction to enhance the performance and durability of the roads:

Geotextiles: These are permeable fabrics made from synthetic materials used for separation, filtration, and reinforcement in road structures.Â

Geogrids: Geogrids are rigid or flexible mesh-like structures made from polymers or other materials. They are used to reinforce the soil and distribute loads, reducing the potential for rutting and increasing the road's overall strength.

Geocomposites: Geocomposites are combinations of different geosynthetic materials, such as geotextiles and geogrids. They offer a range of functions, including separation, drainage, and reinforcement, depending on their specific composition.

Geocells: Geocells are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) or other materials. When filled with soil, they create a stable platform, often used in slope protection and retaining walls.

Geomembranes: These are impermeable membranes used to provide a barrier against water and contaminants. In road construction, they are employed in applications like lining drainage systems and protecting against water seepage.

Geonets: Geonets are mesh-like materials used primarily for drainage applications. They allow water to pass through while providing support to prevent soil compaction.

Each type of geosynthetic serves a specific purpose, and their combination or selection depends on the engineering requirements and soil conditions of the road construction project.

Benefits of Geosynthetics in Road Construction

Geosynthetic materials serve multiple purposes, especially in road construction. They are utilized for separating, confining, and distributing loads, which helps to enhance the stability of structures. Additionally, they play a crucial role in improving level-grade soil situations, making roads, alleys, and laneways more robust and durable.

These materials also contribute to the reinforcement of soil structures, including walls, bridge abutments, box culverts/bridges, and soil arches, ensuring their long-term strength and integrity.

Geotextile separation makes roads last longer and reduces maintenance needs. In construction projects like "floating roads" on weak ground, such as peat-thick land, or where a reinforcement grid alone can't stop soft soils from shifting, geotextiles come into play.

While early efforts were experimental, subsequent experiments have expanded the scope of geosynthetics, leading to extensive use in various engineering applications. Megaplast has mastered the production of high-quality geomembranes, instrumental in numerous road projects in India and internationally. We provide solutions to meet all your needs. For inquiries, contact us at info@mega-group.in or call +91 022 - 6106 6000.

For more information. Please complete this form.